MCR Safety CT1017NF Nitrile Foam Cut-Resistant Safety Gloves

MCR Safety CT1017NF Nitrile Foam Cut-Resistant Safety Gloves maximise grip in wet and dry conditions, making them an excellent option for machine and equipment operation indoors and out in the elements. On top of their excellent manual handling capabilities, MCR CT1017NF Nitrile Gloves protect against sharp metal, timber and glass thanks to their Level D cut-resistance rating.

What's Included?

- 1 x Pair of Cut-Resistant Gloves

Sizing Information for MCR CT1017NF Cut-Resistance Work Gloves

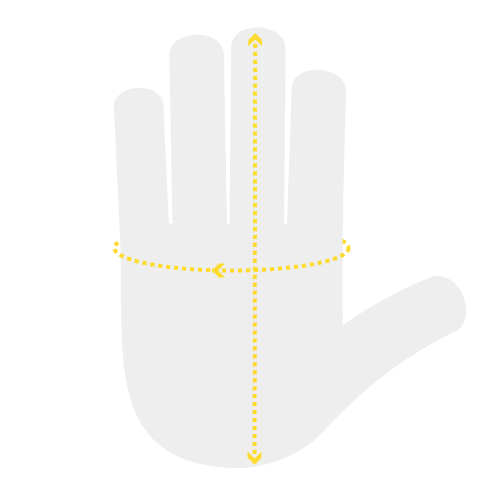

MCR CT1017NF Cut Safety Gloves are available in four different sizes. To find the perfect one for you, simply measure your palm circumference (ignoring the thumb area) and the length of your hand as indicated in the image below.

Once you have your measurements, please consult the sizing chart below to find the correct size for your hand.

| Size | Palm Circumference | Hand Length |

| Size 7 | 178mm | 171mm |

| Size 8 | 203mm | 182mm |

| Size 9 | 229mm | 192mm |

| Size 10 | 254mm | 204mm |

Protection Ratings and Resistance Information

Mechanical Resistance: EN 388

EN 388 is a European regulation governing the sale of gloves used for safety and protection. It determines the gloves' performance when used for protection against mechanical machinery by measuring the fabric's abrasion, cut, tear and puncture resistance.

The EN 388 cut resistance test uses a single sharp implement to repeatedly pressure a glove in order to determine the amount of force required to cause visible and functional damage.

| Hazard | Level of Resistance |

| Abrasion Resistance | Level 4 |

| Cut Resistance | N/A |

| Tear Resistance | Level 4 |

| Puncture Resistance | Level 3 |

| ISO Cut Resistance | Level D |

What Does Level D Cut-Resistance Actually Mean?

Cut Level D Gloves are great for use in areas where it's likely you'll come into contact with sharp metal, exposed glass and blades from time to time. Though they do not offer as much protection as our maximum rated Cut Level F Gloves, they do offer a greater amount of flexibility and control for manual handling in building and construction settings.

Suitable For A Range of Industries

Level D cut-resistance and a sleek and slender design brief make MCR Safety CT1017NF Cut Pro Gloves ideal for use in a range of different environments and areas, including:

- Automotive

- Aerospace

- Assembly

- Building

- Construction

- Forestry

- Gas

- Glass Handling

- Law enforcement

- Metalwork

- Oil

- Petroleum

- Steel Handling

Incredibly Lightweight and Sensitive Design

MCR CT1017NF Safety Gloves are some of the most lightweight cut-resistance gloves on the market thanks to their skin tight fit and slender design brief. This provides the wearer with an exceptional level of comfort and control over the material they're interacting with, making it easier to carry out a range of tricky, intricate tasks.

What Are the Benefits of Foam Nitrile??

Foam nitrile is an incredibly durable and porous coating. It is unparalleled when working around liquids as it works to absorb and suck up water and oil, preventing slips and drops.

It behaves like a sponge, creating a suction cup effect which leaves the user able to grip tightly onto whatever it is they're lifting. Foam nitrile is also three times more puncture resistant than rubber.

Great Dexterity and Touch

Gloves are only as good as the material they allow you to interact with. Big and bulky gloves are no good to anyone operating intricate machinery and tools, because they don't allow the fingertips to interact accurately.

MCR CT1017NF Nitrile Gloves are different. Their slender design promotes a massive amount of natural touch and dexterity, allowing you to make tweaks and changes to switches, bolts, screws and nuts with ease.

Additional Documentation