ATG 44-304 MaxiCut Oil Resistant Double Dip Coated Safety Gloves

Every year, millions of pounds worth of product, equipment and tools is lost on sites because of drops and slips. ATG 44-304 MaxiCut Oil Resistant Double Dip Coated Safety Gloves use a double-dipped nitrile coating to absorb harmful, slick substances that linger unseen on metal, boxes and timber. With Level 4 abrasion resistance, rest-assured these gloves not only enhance grip strength and stability; they are built to last.

What's Included?

- 1 x Pair of Safety Gloves

KEY FEATURES AND ATTRIBUTES

- Highly oil-resistant outer nitrile coating

- Palm and finger coating enhances grip strength in greasy and oily conditions

- Contact heat resistant when handling material with a temperature of up to 100°C

- Across-the-board EN 388 protection

- Double dipped nitrile coating both seals and enhances grip

- Designed for use in contact with grease, oil, petrol and other slick substances

- Flexible and dexterous design makes for a lightweight glove

- Available in four different sizes for a guaranteed perfect fit

Which Size Is Right for Me?

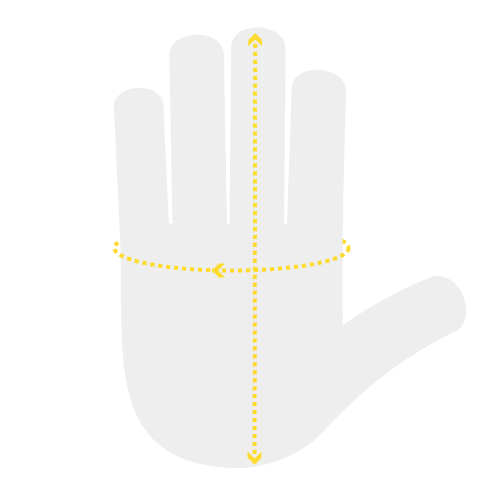

To find your perfect size, simply measure the circumference of your palm (ignoring the thumb area) and the length of your hand as indicated in the image below. Once you have your measurements, please consult the sizing chart below to find the correct size for your hand.

| Size | Circumference of Palm (mm) | Length of Palm (mm) |

| Size 7 (Small) | 178mm | 171mm |

| Size 8 (Medium) | 203mm | 182mm |

| Size 9 (Large) | 229mm | 192mm |

| Size 10 (Extra Large) | 254mm | 204mm |

MaxiCut 44-304 Protection Ratings

EN 388

EN 388 is a European regulation governing the sale of gloves used for safety and protection. It determines the gloves' performance when used for protection against mechanical machinery by measuring the fabric's abrasion, cut, tear and puncture resistance.

The EN 388 cut resistance test uses a single sharp implement to repeatedly pressure a glove in order to determine the amount of force required to cause visible and functional damage.

| Standard | Resistance Rating |

| Abrasion Resistance | Level 4 |

| Cut Resistance | Level 3 |

| Tear Resistance | Level 4 |

| Puncture Resistance | Level 1 |

| ISO Cut Resistance | Level B |

EN 407

EN 407 is a European safety regulation governing the sale of gloves and garments that are resistant to any number of fire, heat and molten related hazards. Please view the table below to find out more:

| Standard | Resistance Rating |

| Burning Resistance | N/A |

| Contact Heat Resistance | Level 1 (100°C) |

| Convective Heat Resistance | N/A |

| Radiant Heat Resistance | N/A |

| Resistance to Small Molten Splashes | N/A |

| Resistance to Large Molten Splashes | N/A |

LEVEL 4 ABRASION RESISTANCE

Abrasion resistance is often under-looked in terms of EN 388. MaxiCut Oil 44-304 Safety Gloves have been awarded the highest possible Level 4 rating. This indicates they can withstand traffic, constant contact and wearing down better than most.

WHAT PROFESSIONS REQUIRE HIGH ABRASION RESISTANCE?

In terms of environments, any professional handling, carrying, lifting and transferring material for a living should be using abrasion resistant safety gloves. Moving packaging, lifting boxes and transferring material can quickly wear the hands down, causing fatigue, strain and blistering.

CONTACT HEAT RESISTANCE TO 100°C

The heat-resistant outer coating allows users to handle material with a temperature not exceeding 100°C for an incredible fifteen seconds. This allows for the safe and secure transfer, disposal and replacement of incredibly hazardous material that can otherwise cause serious injury.

Suitable Applications and Environments for Use

The MaxiCut Protection Promise

ATG's MaxiCut range are highly resistant to a range of common workplace hazards. Please view the video below to see what they can do to protect your hands at work:

Oil Resistant Outer Coating

Every year, millions are lost on sites because of dropped material. Ensure that oil and grease don't compromise the strength and stability of your grip by using a pair of oil-safe work gloves. Their nitrile coating works tirelessly to absorb harmful and slick substances, keeping your hands dry and grippy for longer.

Nitrile Coating Benefits

Nitrile is an incredibly flexible coating that provides additional resistance to oil, fuel and chemicals. Nitrile is used as a protective coating in gloves because it matches the pliability of latex with the hazard and injury protection properties of a heavier, woven glove.

Double Your Protection

For ATG, a single coating is not enough. The first layer of nitrile serves to seal the glove, preventing moisture and liquid from penetrating through the glove fabric. The second layer works to enhance grip strength and stability, ensuring that material and products stay in place.

Additional Documentation